When shopping for steel barricades online, you might encounter various terms related to galvanizing that can be confusing. For example, we offer two types of galvanized barricades: those that are hot-dipped galvanized and those that are pre-galvanized.

Before diving into the differences between these two methods, let’s first review the galvanizing process itself. In this post, we’ll cover:

- What is galvanizing, and why do we do it?

- What is hot-dipped galvanizing?

- What is pre-galvanizing?

- Which method of galvanizing is most effective?

What is "galvanizing" and why do we do it?

Galvanizing is the process of applying a protective zinc coating to steel or iron to prevent rust and corrosion. The most common method involves immersing the metal in a bath of molten zinc, which forms a durable barrier over the surface. This zinc layer protects the metal in two key ways:

- Barrier protection: it shields the underlying steel from moisture and oxygen, which are essential for rust formation.

- Sacrificial protection: The zinc coating acts as a sacrificial anode, corroding preferentially—even if the coating is damaged—thus protecting the exposed metal. Fun fact: Boats often feature a sacrificial anode, commonly referred to as "zincs," to protect other metal parts such as the propeller, rudder, and more from corrosion.

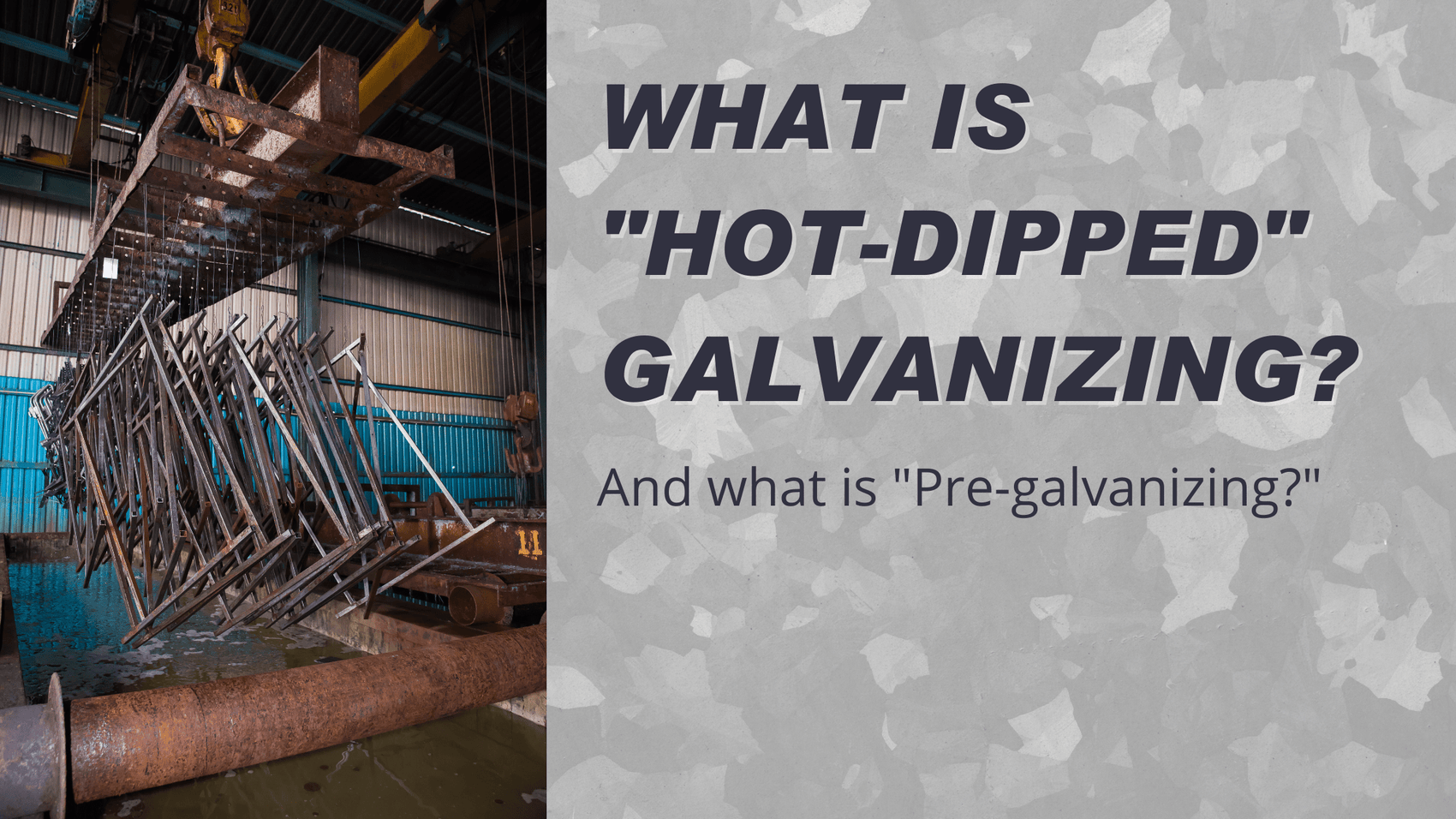

What is hot-dipped galvanizing?

Hot-dipped galvanizing is often used interchangeably with the term "galvanizing." It refers to the process of immersing a fully assembled steel structure—such as our steel barricades—into a bath of molten zinc. This method not only coats the exterior surfaces but also ensures that joints and seams, which are prone to corrosion, receive a robust protective layer.

While all galvanizing involves a molten zinc bath, products labeled as "hot-dipped galvanized" are treated after assembly. This means that rather than applying the zinc coating to individual components before assembly, the entire structure is submerged, resulting in a more comprehensive and durable coating.

Shop hot-dipped galvanized barricades.

What is pre-galvanizing?

Pre-galvanizing is a process where steel is coated with zinc before being cut into pieces for assembly. This protects the main body of the steel, but the edges exposed during cutting may not be fully treated. Because of this, pre-galvanized products are usually cheaper to make and have a thinner coating than hot-dipped galvanized products.

While pre-galvanizing still helps prevent rust, it is less durable—especially outdoors—compared to the thicker, more uniform coating of hot-dipped galvanizing.

Shop pre-galvanized barricades.

Which method of galvanizing is more effective?

The hot-dipped method is generally more effective than pre-galvanizing. Here's why:

-

Comprehensive Coating:

Dipping a fully assembled structure ensures that every part—including joints and seams where components connect—is thoroughly coated. These vulnerable areas are critical since they are most prone to rust. -

Thicker, More Durable Coating:

The post-assembly dipping process results in a thicker layer of zinc. This added thickness enhances durability, offering better long-term protection against corrosion, especially in harsh outdoor environments.

For more information on other barricade features, take a look at our Barricade Buying Guide.